At Junjiang Construction Company, we specialize in providing high-quality power transmission towers that ensure efficient and safe energy distribution across vast distances. Designed to withstand challenging environmental conditions, our power transmission towers are built using the latest materials and engineering techniques. Whether you need a solution for urban energy grids or remote areas, our towers offer the strength, durability, and reliability required for continuous power transmission. Explore our diverse range of power transmission tower solutions, tailored to meet the demands of your infrastructure projects while adhering to the highest safety and regulatory standards.

| Voltage | 10kV to 1100kV |

| Shape of steel | Angular / tubular steel |

| Lattice Type | 3/4 legs lattice |

| Tower Type | Suspension Tower, Tension Tower, Dead Tower, Substation Structure |

| Height | 10M-100M |

| Circuit | Single / Double Circuit |

| Material | 1.High strength low alloy structural steel: Q420B which is equivalent with ASTM Gr60 2.High strength low alloy structural steels: Q355B which is equivalent with ASTM Gr50 or S355JR 3.Carbon Structural Steel: Q235B which is equivalent with ASTM A36 or S235JR |

| Welding | AWS D1.1 |

| Surface treatment | Hot dip galvanizing /painting/Powder coating |

| Hot dip galvanization | GB/T 13912-2002, EN ISO 1461,ASTM/A123 or equivalent |

| Welding Standard | AWS D1.1, AS554, AS 4100 standard or equivalent |

| Earthquakeproof Grade | Grade 8 |

| Ice wrapping | 5-10 mm |

| Verticality | 1 / 1000 |

| Working Temperature | - 45°C -+ 45°C |

| Nuts& Bolts | Mainly ISO 898 grade 6.8 and 8.8 bolts for Both Chinese, ISO and DIN standard |

| Working lifespan | 30/50 years |

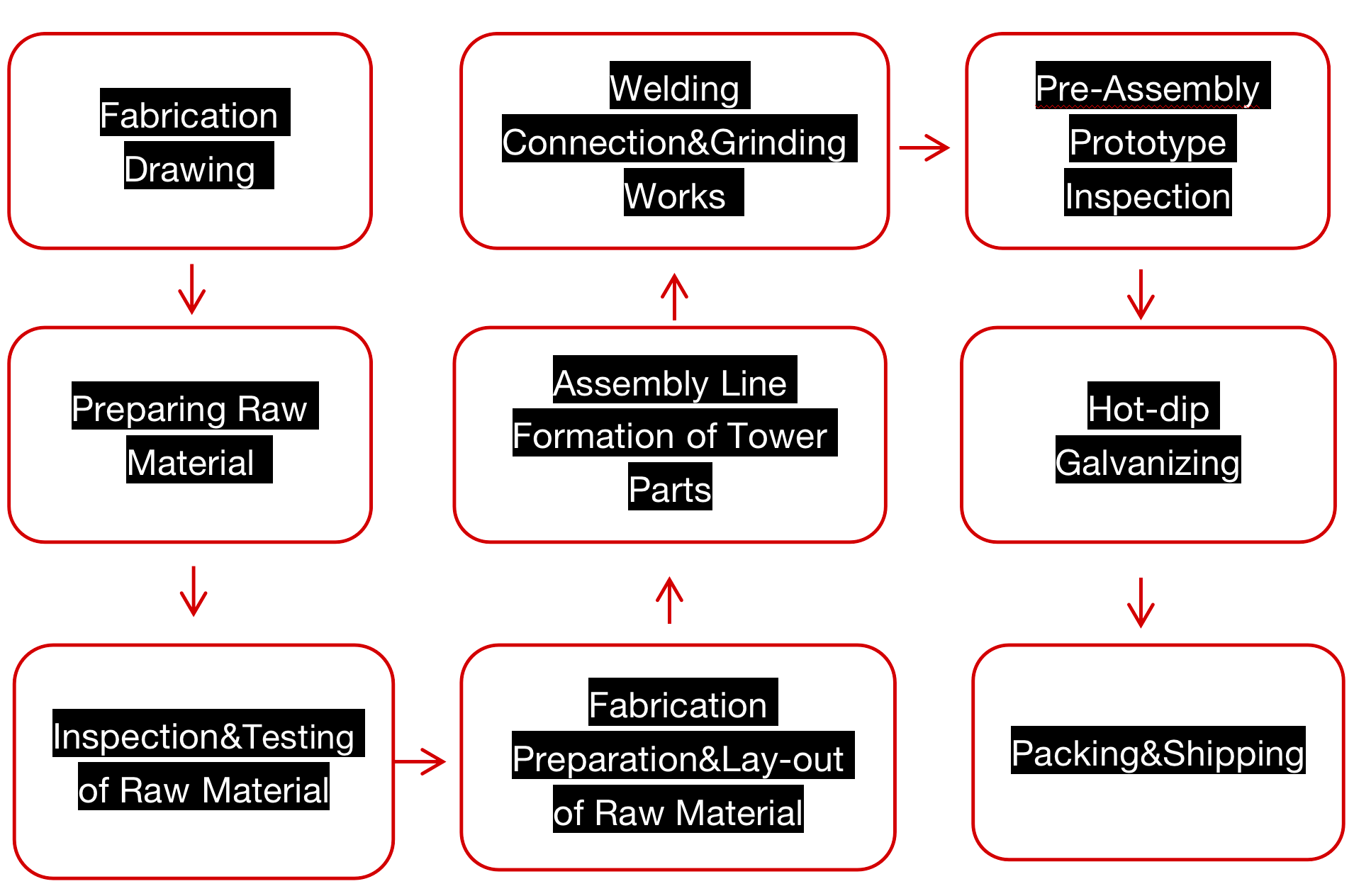

Junjiang is a transmission line tower manufacturer and supplier located in China. We can manufacture three different categories of electric transmission towers, which accommodate 750KV and 1000KV high voltage, 500KV, and 220KV transmission lines respectively. In addition, we can also manufacture different types of steel towers, including steel lattice transmission towers, guyed towers, and self-supporting towers, etc.

Performance Standard

Besides conforms to the drawing and design, the materials and fabrication of tower components shall conform to the following standards (Chinese Standards).

Junjiang uses CO2 welding and submerged arc auto welding, along with other methods, to meet the welded requirements. The welded seams are fully penetrated and ground. The welded products have no fissures, scars, overlaps, layers, or other defects.

Galvanization:

All components are dip-hot galvanized with uniform coating.

Certification:

Junjiang also supplies Factory Acceptance Tests, Warranty Certifications, and Certificates of Product Quality. Additionally, we provide Certification of the Quality Management System.

We are equipped with the leading CNC transmission line angle tower production line and CNC plate processing line which is introduced, also with other 200 sets of fabrication equipment,to assure the proper manufacturing and quality of steel tower projects.