Imagine a day without electricity. No lights, no internet, no charging your phone. Electrical cable towers silently prevent this chaos every day by delivering power across cities and countries. Electrical cable towers are steel structures that support overhead power lines, safely transmitting electricity across long distances while withstanding weather extremes and environmental stresses. These unsung heroes of our power grid might look simple, but their engineering—often perfected by experienced electric tower manufacturers such as Junjiang Construction—is crucial. Without them, modern life would literally collapse. Let's explore how these structures keep our lights on.

You've seen them lining highways and spanning valleys, but what exactly makes these steel giants so vital to our electricity supply? Cable towers maintain safe clearance for high-voltage lines, prevent power loss over distances, and create stable pathways for electricity to travel from plants to homes and businesses.

Electrical cable towers serve three critical functions in power distribution:

| Feature | Benefit |

|---|---|

| Galvanized steel construction | Resists corrosion for 50+ years |

| Triangular lattice design | Maximizes strength-to-weight ratio |

| Deep foundations | Withstands 150mph winds |

Insulator strings prevent current leakage

Ground wires protect against lightning

Safety clearances prevent arcing

Tall towers enable:

Longer spans between supports

Higher voltage transmission

Reduced power loss over distance Modern towers incorporate seismic dampers and vibration-resistant designs to survive earthquakes. Their height also protects wildlife and prevents vegetation interference.

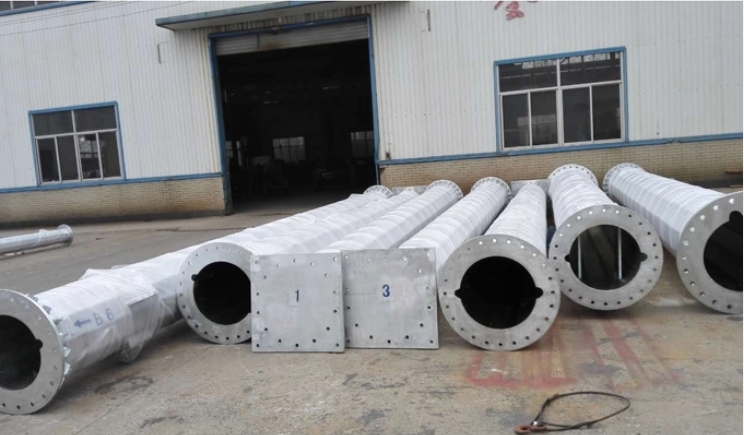

When you look at those metal giants along the highway, what are you really seeing? Let's break down their anatomy. An electrical cable tower is a specially engineered metal structure that elevates and supports high-voltage power conductors at safe heights above ground and from each other.

Foundation

Concrete piers extending 10-30ft underground

Stabilizes entire structure

Resists uplift forces

Legs & Bracing

Typically 4-legged design

Cross-bracing for lateral stability

Adjustable for terrain slopes

Arms & Insulators

Horizontal beams supporting conductors

Porcelain/polymer insulators

Configurable for different voltage levels The spacing between phases varies by voltage:

| Voltage Level | Typical Spacing |

|---|---|

| 115kV | 6-8 feet |

| 230kV | 10-12 feet |

| 500kV | 15-20 feet |

Why do engineers prefer these steel structures over underground cables for most high-voltage transmission? According to experienced steel tower suppliers, cable towers provide cost-effective, reliable power transmission with lower maintenance needs than underground alternatives, while allowing easy capacity upgrades and visual fault detection.

Installation costs 5-10 times less than underground

Requires simpler maintenance equipment

Lower repair costs and faster repairs

Better heat dissipation prevents overheating

Natural cooling extends cable lifespan

Higher voltage capacity possible

Easy visual inspections

Faster fault location

Simple capacity upgrades Environmental Factors:

Lower electromagnetic field exposure

Reduced right-of-way requirements

Better compatibility with existing infrastructure Modern towers now incorporate bird flight diverters and noise-reduction designs to further minimize ecological impact.

With so many tower designs available, how do you select the optimal solution for your power project? When evaluating a steel tower for sale, consider voltage requirements, environmental conditions, span length, and future expansion needs. Choose between lattice, monopole, or guyed structures based on project priorities and long-term performance expectations.

| Tower Type | Typical Voltage Range |

|---|---|

| Distribution | 11kV-33kV |

| Subtransmission | 66kV-132kV |

| Transmission | 220kV-800kV |

| Type | Pros | Cons |

|---|---|---|

| Lattice | Lowest cost, Lightest weight | Requires more land |

| Monopole | Compact footprint, Aesthetic | Higher material cost |

| Guyed | Long spans possible | Needs anchor space |

Wind load requirements

Ice/snow accumulation

Seismic activity risk

Corrosion potential Always consult structural engineers for custom projects. Consider maintenance access and future upgrades during selection.

Electrical cable towers form the silent backbone of our power networks, delivering electricity safely and efficiently across vast distances using proven, adaptable steel structures.