Need strong towers for power lines or communications? Outdated designs can be inefficient or fail under pressure. Modern steel tower construction relies heavily on innovative design principles for safety and reliability. Design and innovation in steel tower construction are driven by the need for greater structural efficiency, enhanced safety under extreme loads, optimized material use, faster construction, and reduced environmental impact, using advanced engineering and materials. ! I've seen the evolution of tower design firsthand over the years. Early towers were often overbuilt, using more steel than necessary. Now, with advanced software and a better understanding of materials, we at Junjiang Construction can create incredibly strong yet efficient structures. It's fascinating how engineering pushes the boundaries. We focus on building towers that are not just strong but also smart – considering everything from the specific loads they'll carry to how they fit into the environment. Let's look at the core ideas behind modern steel tower design.

Building a tower that won't fall over seems simple, right? But these structures face immense forces. Poor design calculations or ignoring basic principles can lead to catastrophic failures. Key design principles involve accurately calculating all potential loads (wind, ice, equipment weight), ensuring structural stability against buckling, designing reliable connections, selecting appropriate materials, and strictly adhering to relevant engineering codes. ! I remember one project where wind load calculations were particularly tricky due to the local geography. We had to run multiple simulations to ensure the design was robust. Getting the fundamentals right is non-negotiable in tower construction. It's the bedrock of safety and performance.

The first step is figuring out everything the tower needs to support or resist.

Dead Loads: The weight of the tower structure itself, plus any permanently attached equipment like antennas or conductors.

Live Loads: Temporary loads, mainly from wind acting on the tower and anything attached to it. This is often the biggest factor.

Environmental Loads: Ice accumulation adds significant weight and increases the area exposed to wind. Seismic loads are critical in earthquake-prone regions.

Construction & Maintenance Loads: Temporary stresses during erection or when workers climb the tower.

A tower needs to stand tall without collapsing or buckling. Engineers analyze:

Overall Stability: Preventing the tower from overturning due to wind or other forces. This depends heavily on the foundation design.

Member Stability: Ensuring individual steel members (legs, bracing) don't buckle under compression loads. The shape and connection of these members are crucial.

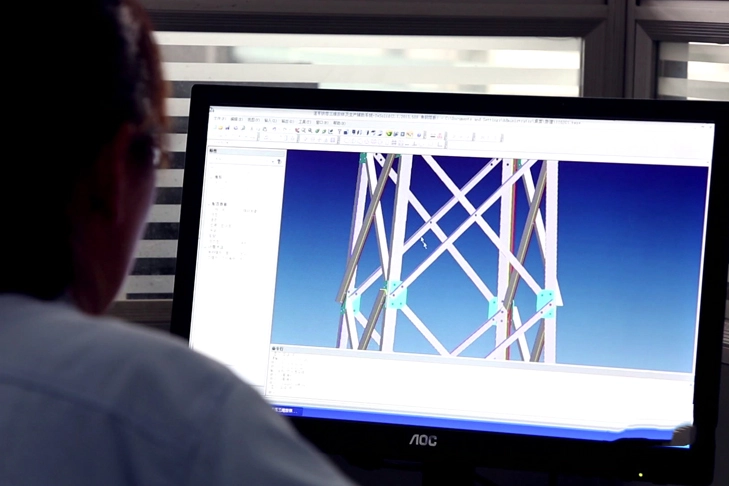

The points where steel members join are critical. Connections (usually bolted in lattice towers) must be strong enough to transfer forces between members without failing. The number, size, and grade of bolts are carefully calculated. Proper detailing ensures connections behave as expected under load. Reliable design principles, often aided by specialized software, form the foundation of every safe and efficient tower we build at Junjiang.

Towers stand exposed to weather for decades. Using the wrong steel or having hidden flaws can lead to rust or sudden breaks. Assuring material quality is essential for long-term safety. Proper steel selection ensures the tower has the necessary strength, toughness (resistance to fracture), and durability (corrosion resistance). Rigorous quality control verifies these properties and checks fabrication quality, preventing premature failures. ! We once had a supplier try to substitute a lower grade of steel on a small component. Our receiving inspection caught it immediately. You simply cannot compromise on material quality when building critical infrastructure like towers. That's why our quality control at Junjiang is so strict.

Not all steel is the same. Key properties for tower design include:

Yield Strength: The stress level at which the steel starts to deform permanently. Higher yield strength often means lighter members can be used.

Tensile Strength: The maximum stress the steel can withstand before breaking.

Toughness: The ability to absorb energy and resist fracture, especially important in cold temperatures or under dynamic loads (like wind gusts or earthquakes). Different steel grades are specified based on the calculated stresses and environmental conditions.

Steel rusts. Protecting it is vital for the tower's lifespan. Common methods include:

Hot-Dip Galvanizing: Coating the steel members with a layer of zinc. This provides excellent, long-lasting protection even if the surface gets scratched. This is the most common method for lattice towers.

Painting Systems: Applying specialized paints over a prepared surface. Often used for monopoles or where specific colors are needed. Requires maintenance over time.

QC happens at multiple stages:

Mill Certification: Verifying the steel supplier provides material that meets the specified grade and chemical composition.

Fabrication Inspection: Checking cutting, drilling, and welding accuracy in the workshop. Non-destructive testing (NDT) like ultrasonic or magnetic particle testing might be used to find hidden weld flaws.

Trial Assembly: Sometimes done for complex towers to ensure parts fit correctly before shipping.

Receiving Inspection: Checking components upon arrival at the site. This meticulous process ensures the final tower matches the design specifications and is built from sound materials.

Need a very tall tower but want to minimize costs and material usage? Balancing strength with efficiency is key. Ignoring safety standards to save money is unthinkable and illegal. Structural efficiency involves using analysis and design techniques (like Finite Element Analysis) to optimize member sizes and tower geometry, minimizing steel weight for the required load capacity. Safety standards (e.g., TIA/EIA-222) provide mandatory minimum requirements for loads, analysis methods, and safety factors. ! We often use sophisticated software to refine tower designs. It helps us find the sweet spot where the tower is strong enough to exceed safety standards but doesn't use excessive, costly steel. It’s about smart engineering guided by essential safety rules.

An efficient tower carries the required loads using the least amount of material possible, reducing cost and environmental footprint.

Lattice Towers: These are often very efficient for tall structures carrying heavy loads (like high-voltage transmission lines). The open framework uses triangulation, putting members primarily in tension or compression, which steel handles very well.

Monopoles: Tubular steel poles are often used for communication towers or where aesthetics are important. They can be less efficient structurally than lattice towers for very high loads but offer a smaller footprint and cleaner look.

Optimization Software: Tools like Finite Element Analysis (FEA) allow engineers to model the tower digitally, analyze stresses in detail, and adjust member sizes or geometry to optimize weight without compromising strength.

Standards are non-negotiable rules that ensure public safety.

Key Standards: In North America, TIA/EIA-222 is the primary standard for communication towers. Other standards exist for transmission towers (like ASCE guidelines). These standards are developed by industry experts and are legally mandated in many places.

What They Specify: Standards define minimum design loads (wind speeds, ice thickness), required load combinations, analysis procedures, allowable stresses or strengths for materials, required safety factors (multipliers applied to loads or resistances), and sometimes requirements for foundations and construction. Engineers must design towers to meet or exceed these standards. Compliance ensures a minimum acceptable level of safety and reliability. At Junjiang, meeting these standards is the absolute baseline for all our designs.

Building a large steel structure inevitably impacts the surroundings. Ignoring visual impact or local ecology can lead to project delays or rejection. Considering the environment early is crucial. Environmental considerations include minimizing visual impact through careful siting and design (including camouflage options), reducing the physical footprint, protecting sensitive habitats during construction, and using materials and processes with lower environmental burden, like recyclable steel. ! I worked on a project routing a transmission line through a scenic area. We spent significant time analyzing sightlines and adjusting tower locations and types to minimize how much they stood out. It added complexity but was essential for gaining approval.

Towers can be seen from miles away. Strategies to reduce their visual intrusion include:

Siting: Placing towers away from sensitive viewpoints, using topography to screen them, or aligning them with existing linear features (like roads).

Design Choice: Sometimes a monopole is preferred over a lattice tower for a less cluttered look, even if structurally less efficient. Using dull finishes or specific colors can help towers blend into the background.

Camouflage: Disguising monopoles as trees or flagpoles, particularly for communication towers in populated or scenic areas.

Towers require land for their base and construction access.

Foundation Optimization: Designing the smallest feasible foundation minimizes ground disturbance. Monopoles generally have a smaller footprint than lattice towers.

Site Selection: Avoiding wetlands, critical habitats, or culturally significant areas is paramount. Environmental impact assessments are often required.

Construction Practices: Using existing access roads where possible, controlling erosion during construction, and restoring disturbed areas after completion help minimize long-term impact.

Steel itself offers environmental benefits:

Recyclability: Steel is highly recyclable. Using recycled content in new steel reduces energy consumption and raw material extraction. Towers can be fully recycled at the end of their life.

Durability: Long-lasting protection like galvanizing extends the tower's service life, reducing the need for replacement and associated environmental impacts. Considering these factors throughout the design and construction process helps balance the need for infrastructure with environmental stewardship.

Innovative steel tower design successfully balances structural efficiency, stringent safety standards, material quality, and environmental responsibility. At Junjiang, we are committed to delivering expertly engineered, reliable, and thoughtfully designed tower solutions.