An electrical steel pole is a critical component in modern power transmission and distribution systems, offering advantages such as high strength, corrosion resistance, and space efficiency. However, proper installation is essential to ensure safety, structural stability, and long-term performance. This article outlines the key considerations for installing an electrical steel pole, with a focus on site preparation, foundation design, erection methods, and safety compliance.

Before installing an electrical lattice steel pole, a comprehensive site survey must be conducted. This includes evaluating the soil condition, determining elevation levels, identifying underground utilities, and ensuring accessibility for machinery. A well-prepared site reduces risks during construction and ensures the electrical steel pole performs reliably in its environment.

| Task | Purpose |

|---|---|

| Soil testing | Determines load-bearing capacity |

| Underground utility check | Prevents cable or pipeline damage |

| Access route planning | Ensures safe transport and equipment access |

Accurate site data forms the foundation for safe and efficient installation.

The foundation is crucial for supporting the electrical steel pole under various mechanical and environmental loads. Depending on soil type, wind zone, and pole height, engineers must select a suitable foundation type—typically direct embedment or base plate with anchor bolts.

Key factors in foundation design:

Soil bearing capacity: Determines the depth and type of foundation

Wind load and pole height: Affects foundation diameter and reinforcement needs

Drainage considerations: Prevents water accumulation and corrosion at the base

Properly engineered foundations help prevent tilting, sinking, or structural failure of the electrical steel pole.

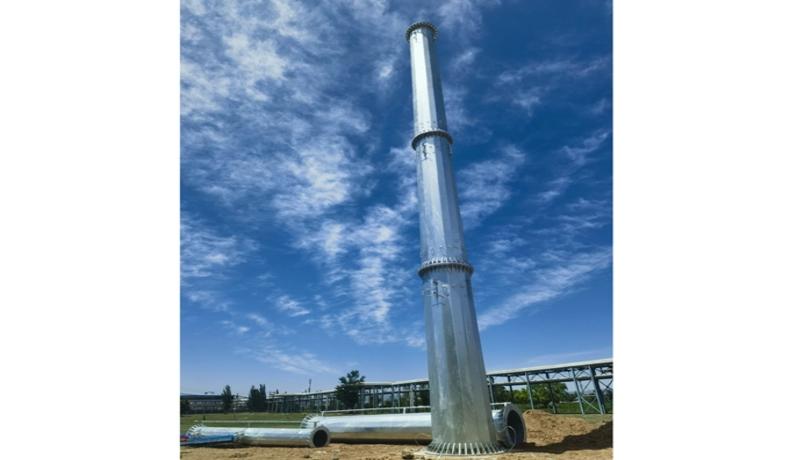

The erection process of an electrical steel pole must follow strict alignment and leveling procedures. Cranes or derrick trucks are commonly used for lifting and positioning. During this stage, care must be taken to avoid damage to the galvanization or coating, and following the best practices recommended by a reliable transmission line tower manufacturer can further ensure long-term durability and performance.

Installation Tips:

Use non-abrasive slings to protect pole surface

Align pole vertically using a plumb line or laser level

Torque anchor bolts according to specifications

Inspect all joints and fasteners after assembly

Precise erection ensures the electrical steel pole remains stable and performs reliably under operational stress.

Compliance with national electrical and structural safety standards is mandatory when installing an electrical steel pole. All personnel must use appropriate PPE (Personal Protective Equipment), and the site should be secured to prevent unauthorized access.

| Inspection Item | Objective |

|---|---|

| Bolt torque verification | Ensures structural integrity |

| Verticality and leveling | Confirms correct pole alignment |

| Grounding system check | Protects against lightning and electrical faults |

| Surface condition | Identifies coating damage or rust spots |

Only after passing a full inspection should the electrical steel pole be commissioned into service.

Proper installation of an electrical steel pole is essential for safety, structural integrity, and system reliability. Whether applied in new infrastructure projects or when evaluating steel towers for sale, every stage — from initial site preparation to final inspection — must be executed with precision and in compliance with engineering standards. By following these guidelines, project stakeholders can ensure that the electrical steel pole will operate efficiently and safely for decades to come.