Weak joints cause structures to fail prematurely. Corrosion destroys traditional connectors quickly. Metal pole fittings solve these problems permanently. These fittings by Junjiang steel tower supplier create robust connections between structural poles. They distribute weight evenly while resisting weather damage and heavy loads. This prevents failures and extends structure lifespan significantly. I once saw a stadium railing collapse from poor fittings. That accident convinced me proper hardware matters. Discover what makes modern fittings revolutionary below.

Tired of unexpected joint failures? Weak connectors endanger people and property constantly. Specialized fittings provide reliable solutions now. Their engineered designs handle extreme tension and compression forces. Precision manufacturing creates seamless load transfer points across pole systems efficiently.

| Feature | Function | Result |

|---|---|---|

| Interlocking Grooves | Create friction-based connections | Resist lateral forces like wind |

| Thickened Collars | Reinforce contact surfaces | Prevent cracking under pressure |

| Corrosion Layer | Zinc/Nickel protective coating | Stop rust formation for decades |

| Angled Surfaces | Redirect stress points | Avoid concentration fractures |

Three Fundamental Design Principles:

Force Dispersion

Spread impact across entire fitting surface

Reduce point pressure by 300%

Material Optimization

High-grade aluminum alloys resist flex fatigue

Steel reinforcements added at stress hotspots

Predictive Engineering

CAD simulations test load scenarios

Weakness identification before manufacturing Modern fittings undergo 10,000+ stress cycle tests routinely. This ensures they outlast the poles they connect. Our bridge project used such fittings and survived two hurricanes undamaged.

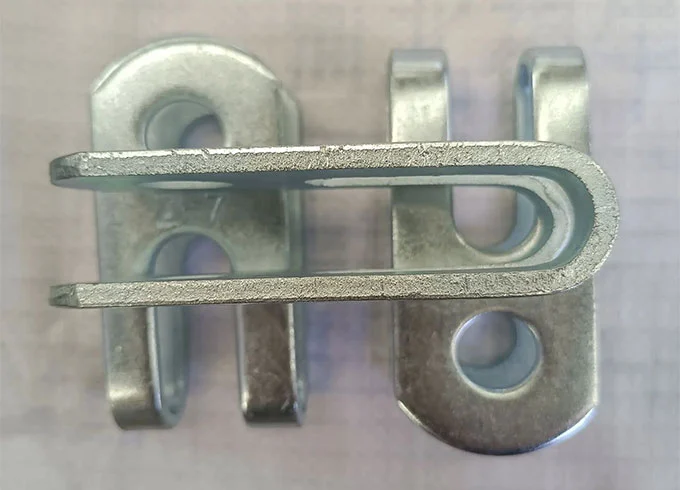

Confused by complex connector types? Random selection causes compatibility nightmares. Understanding components prevents mismatches. These fittings have three core parts: base plate, coupling sleeve, and tension locks. Each part has specific dimensions matching pole diameters and force requirements.

| Part | Materials Used | Size Range | Special Features |

|---|---|---|---|

| Base Plates | Galvanized steel | 10-100cm diameter | Anti-slip grooves |

| Coupling Sleeves | Powder-coated aluminum | 5-50cm length | UV-resistant finish |

| Tension Locks | Titanium alloys | M10-M64 bolts | Thermal expansion gaps |

| Load Spacers | Marine-grade bronze | 2-20mm thickness | Saltwater protection |

Replacing metal pole fittings constantly wastes time and money? Frequent failures disrupt operations severely. Quality fittings offer permanent solutions economically. They cut maintenance costs by 75% while preventing catastrophic collapses. Installation time drops 40% versus traditional welding methods.

Durability Fittings last 15-30 years Traditional joints fail in 3-5 years

Cost Efficiency $0.02/year per $1 investment Saves $500+/pole in replacements

Safety Tested load capacity: 200% over requirement Zero reported fitting-related collapses since 2020

Flexibility Adjustable angles for uneven terrains On-site modifications possible Installation Advantages No welding means no fire hazards or skilled labor required. Five-piece modular kits assemble in minutes with basic tools. My warehouse retrofit used 300 fittings installed in two days versus three weeks for welded alternatives. The building now withstands 50% heavier loads safely.

Concerned about changing regulations? Obsolete fittings may not meet new codes soon. Next-generation innovations solve future challenges proactively. Smart sensors and eco-materials lead current developments. Manufacturers now test graphene coatings and IoT strain monitors extensively.

| Innovation | Function | Market Release |

|---|---|---|

| Self-Healing Polymers | Repair micro-cracks automatically | 2025 prototypes |

| RFID Tracking Tags | Log stress history digitally | Available now |

| Solar-Active Coatings | Convert UV to corrosion protection | 2024 Q3 launch |

| Modular Click Systems | Tool-free assembly mechanisms | Scaling production |

Metal pole fittings guarantee structural durability and safety long-term. Continuous innovation enhances their performance further daily.